Professional and Precise. It’s Universal.

248.377.0000

Professional and Precise. It’s Universal.

248.377.0000

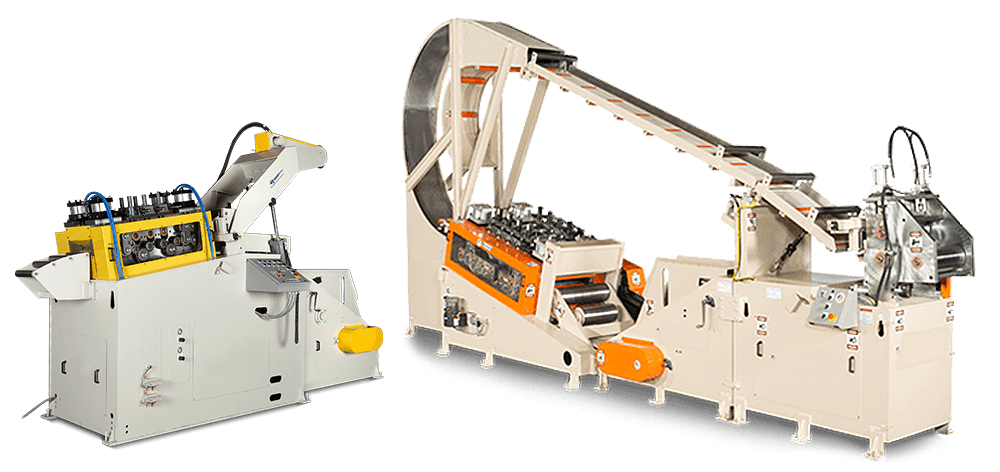

Universal Feed & Machine builds coil cradles in capacities from 4,000 Lbs. to 60,000 Lbs. These cradles have been in our customers' facilities for decades and are a solid proven design. Our Smart. Tough. Proven. cradle designs are designed for even the most challenging stamping environments. Cradles are available with pinch rolls or a powered straightener in the base. We have an array of deflector heights (depending on material thickness and line speed) and chutes style to fit virtually any application. We also have some innovative options such as our hydraulic tilting pinch roll assembly and, peeler/breaker to help thread thick coils. We can modify our standard design to meet a large variety of special applications as well.

Small but simple and easy to operate this unit includes power driven pinch rolls and an AC variable frequency drive for automatic variable speed payout. Numerous options are available to further enhance productivity.

This large cradle includes a powered straightener in the base. These heavy-duty systems are ideal for thick material that is difficult to handle and where coils do not need to be rewound.

Optional hydraulic tilting pinch rolls assembly enhances operator safety by enabling the operator to direct heavy-gauge material to the feed system hands free.

Inline Powered Straighteners with heavy duty cluster gear drive train to remove coil set from your most challenging jobs.

Hydraulic peeler/breaker assembly - used for hands-free threading of thick materials. Induces a reverse-bend allowing the lead edge of the material to be easily thread up.

GET THE UNIVERSAL FEED & MACHINE EXPERIENCE.

Give us a call at (248) 377-0000 to start increasing productivity on your factory floor.