Professional and Precise. It’s Universal.

248.377.0000

Professional and Precise. It’s Universal.

248.377.0000

No matter what your specifications are, Universal Feed & Machine has a straightener to handle your requirements. Our heavy duty construction is seen as one of the most "well engineered products in the Industry." We offer light to medium duty straighteners, Series MPS150, 250, 350. We also offer our Heavy Duty models, the HDPS Series, that are engineered and built for the "Tough" jobs.

The increased challenges of today's "Dual Phase" and other high yield materials have allowed us to utilize our enhanced technologies in straightening applications. Universal Feed & Machine Corporation's Heavy Duty HDPS straighteners are superior to anything our competition has to offer. Our HDPS-8.00 is the premier model and can handle the toughest of applications including materials of up to 965 Mpa (140 KSI) yield strength.

The MPS Series of power straighteners is designed to provide the straightening capabilities required for light to medium stamping applications. This series is typically matched with our Series RF-2.5 and RF-3 servo roll feeds. Systems are typically set up to pull material off from 1,500lb. - 20,000lb. coil reels.

The straighteners include precision ground side plates and tie-bars. The straightener can include (7, 9 or 11) straightening rolls, depending on the application.The straighteners include independent adjustment of the upper straightening rolls with true tonnage adjustment. This design allows up to 1.00” of roll penetration past tangent for greater flatness capabilities and an AC variable speed direct drive which makes this series of straighteners a great value in the market.

| Model | Thickness | Model | Thickness |

|---|---|---|---|

| MPS250-12 | 0.187 | MPS350-12 | 0.21 |

| MPS250-18 | 0.162 | MPS350-18 | 0.185 |

| MPS250-24 | 0.137 | MPS350-24 | 0.16 |

| MPS250-30 | 0.112 | MPS350-30 | 0.135 |

| MPS250-36 | 0.087 | MPS350-36 | 0.11 |

| MPS350-42 | 0.085 |

High-torque, AC variable frequency drives. Motor and reducer are direct drive to lower entrance pinch roll.

High-torque jacks used for straightener roll adjustment provide superior alignment and reduced operator effort (5:1 ratio). All rolls are individually adjusted. True Tonnage at each straightening roll.

All pinch and lower straightener rolls driven through a precision gear train. Roller bearings are sized to exceed specified loads, and rotating and striking surfaces are flame hardened (RC 58-62).

The HDPS series is a Universal Feed & Machine original. This series of straightener has been built by Universal Feed & Machine Corp for over 4 decades. This proven design is based on an extremely rugged foundation. These straighteners can be used in large variety of applications including conventional systems, cradle lines, as well as a standalone parts straightener. The HDPS series begins with straighteners having 3.00" diameter straightening rolls and leads up to our master straightener having 8.00" diameter rolls! They are well suited for light, medium and heavy gauge material. These units can handle the very highest strength materials!

Features:

Heavy-Duty Peeler/Threader/Hold-Down Arm

Motorized edge guides

Secondary lead edge threader/debender.

Laser Loop Control

Outboard Bearing Support

Exit Thread Table - Side Gate Style

Automatic Lubrication System

Exit Thread Table - Scissor-Lift Style

Motorized Adjustment of Upper Straightener Rolls - can be automatically adjusted based on recipe

Tie Plate - Squares Reel to Powered Straightener

Electronic Digital Roll Position Readout

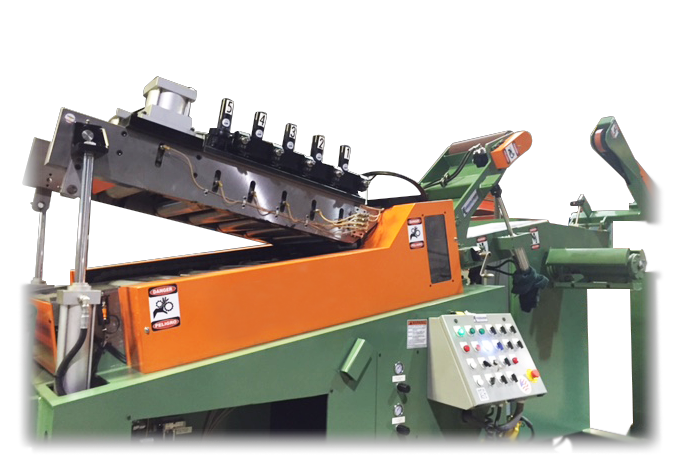

Hand-crank Adjusted Vertical Edge Guides

"There has got to be a better way!" This exclamation is sure to have been heard over and over again in many a stamping plant. Why the frustration? Because trying to clean metal chips, paint, etc. from the rolls of a conventional powered straightener is a slow and cumbersome project that chews away at productions uptime. "There has got to be a better way!" Well, now there is. UFM now offers a pivoting straightener head opening for quick and effective straightener roll cleaning. Pivoting the head open with the upper rolls lifting in a way similar to that of the opening of an alligator’s mouth, these "Alligator" head straighteners provide a vastly improved way of cleaning the rolls of a powered straightener.

The "Safe" mode ensures operator safety during opening/closing, jog, and cleaning. Hydraulic cylinders provide power and control for open/close.

GET THE UNIVERSAL FEED & MACHINE EXPERIENCE.

Give us a call at (248) 377-0000 to start increasing productivity on your factory floor.